- Address: Lot No. 20, Zone G, D1 Street, An Ha Industrial Park, Tan Vinh Loc Commune, Ho Chi Minh City

- Phone: (84-28) 668.36156 / 668.36158

- Hotline: 1800.9435

- Fax: (84-28) 3620.4694

- Email: vibo@vibo.com.vn

- Website https://vibo.com.vn/

A new tool in the battle against decapod iridescent virus (DIV-1)

A new tool in the battle against the decapod iridescent virus (DIV-1)

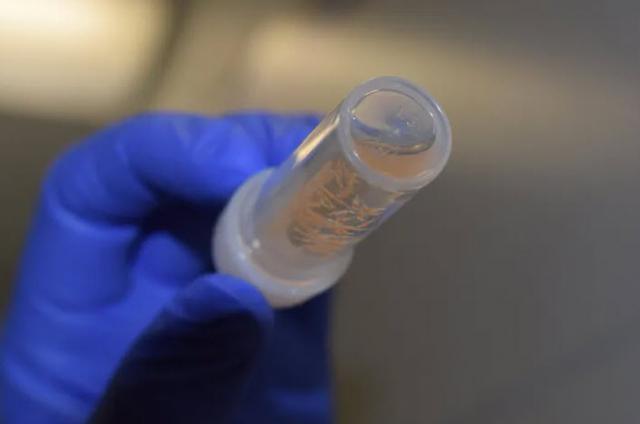

A new diagnostic tool that can detect a range of aquatic pathogens, including DIV-1, between two and four weeks before clinical signs are apparent to shrimp farmers, has recently been launched by Genics.

Genics' MultiPath technology is now being used in 23 countries and covers over 90 per cent of all Australian shrimp/prawn producers

Dr Melony Sellars, CEO of the Australian company, talks to The Fish Site about shrimp pathogens, founding a startup, and the wisdom of shrimp farmers.

Why is a decapod iridescent virus (DIV-1) such a major concern for shrimp farmers?

DIV-1 causes mass mortalities and has been reported now in the two major shrimp culture species – L. vannamei and P. monodon. It can affect late post-larvae, juvenile and sub-adult shrimp, mainly during low-temperature seasons. It is a robust DNA virus and has the potential to spread in uncooked commodities and frozen or fresh live feed ingredients for broodstock shrimp.

How does your device help to tackle this and other pathogens?

Shrimp MultiPath Xtra acts as an early warning system for farmers, alerting them that pathogens are present before they see clinical signs of disease. We can detect a pathogen two to four weeks before a farmer sees the first clinical signs of disease, meaning there is time for early risk mitigation strategies to be implemented. Risk mitigation can be as simple as not sharing nets with other ponds, increasing biosecurity around impacted ponds, letting neighbours know of the biosecurity risk, increasing aeration, reducing feed rate or planning early harvest. In the case of pathogens that cause high mortality like WSSV [whitespot] and DIV-1, MultiPath Xtra can be the difference between harvesting or not harvesting at all. In the case of IHHNV [infectious hypodermal and hematopoietic necrosis], MultiPath Xtra can boost production by up to USD $52K per hectare through only stocking low or no load IHHNV post-larvae.

Shrimp MultiPath Xtra can detect a range of pathogens, including DIV-1

How easy is it to use the system?

Genics offer Shrimp MultiPath Xtra as a service from our ISO17025 accredited service laboratories in Australia. Shipping shrimp samples to Australia in 70 per cent ethanol is a simple process and takes 3-4 days from most regions of the world. Once samples arrive in the lab we can provide data back within one business day. Genics provide a range of complementary educational videos on dissection and collection of tissue samples. Our expert team can also work with a farm to design customised health management plans.

What has industry uptake been like to date?

Genics are now servicing 23 countries with MultiPath technology, with many repeat and dedicated customers. In Australia Genics services over 90 per cent of the total market.

What other measures should farmers take to reduce the likelihood of contracting DIV-1?

Farmers should thoroughly evaluate all the biosecurity risks and pathogen entry points on their farm – including people, live, fresh or frozen broodstock feeds, intake water and broodstock. Farms should ideally have a health surveillance programme and a biosecurity plan in place. Health surveillance can be as simple as routine pathogen screening of a subset of animals from each crop and can be highly cost-effective, and deliver empowering farm management data.

What should farmers do if DIV-1 is detected in their sites?

Detection should be reported to the relevant authorities immediately, which will vary from country to country. From here the farm biosecurity plan should be implemented and followed.

What makes shrimp more susceptible to the disease?

Healthy shrimp are less susceptible to disease. Good pond environment, water quality, high-quality feed and good shrimp genetics all play a critical role.

Dr Melony Sellars established Genics while working at CSIRO in 2017

What do you think are the biggest biosecurity challenges facing shrimp farmers?

There are several key challenges. The lack of sufficient quantities of pathogen-free live and fresh frozen feeds for broodstock maturation or a lack of a suitable maturation diet that can be heat extruded to render pathogens inactive is a key challenge. Access to high health domesticated broodstock to all shrimp farming regions can also at times be prohibitive either by cost or due to geographical and political challenges.

What inspired you to start up your own company?

I worked at CSIRO for nearly 20 years, developing novel biotech solutions for the national and international shrimp industry. One of those tools evolved into what is now known as Shrimp MultiPath. Back in 2017, I asked CSIRO if I could start a company and take the tech to market. After several business and accelerator programmes, here we are today, with Genics holding an IP licence from CSIRO for the tech, and I am taking it to market as a CEO. It’s a fantastic feeling and I am 100 per cent dedicated to transforming how we farm and manage shrimp under culture by better understanding the number one risk to production, pathogens and the diseases they cause.

When you develop technology as a scientist that can really disrupt and change an industry, it’s heart-breaking if it doesn’t make it from the research bench to a commercial product. Before the invention of MultiPath, I had already finalised several biotech products that were only available to industry through collaborative R&D. It was disappointing when I would receive enquiries from the industry all around the world to access the tech but I was never able to provide access. When we had moved beyond proof-of-concept and demonstrated that MultiPath could actually work, I knew the best way to make it available to the entire shrimp industry was to take it to market myself. That’s when I started to think about establishing Genics and approached CSIRO to ask if I could commercialise MultiPath.

Do you have any advice for people looking to start their own aquaculture businesses?

There are many fabulous people in our industry willing to help and give advice and feedback. Spend some time getting to know who they are and reach out for their advice early. Listen, listen, listen to the industry members, especially the long-standing farmers who have been doing this for many years. They are full of good advice.

By Rob Fletcher - The Fish Site