- Address: Lot No. 20, Zone G, D1 Street, An Ha Industrial Park, Tan Vinh Loc Commune, Ho Chi Minh City

- Phone: (84-28) 668.36156 / 668.36158

- Hotline: 1800.9435

- Fax: (84-28) 3620.4694

- Email: vibo@vibo.com.vn

- Website https://vibo.com.vn/

TOXIC GAS MANAGEMENT IN SHRIMP POND

1. Causes of Formation

• Incomplete pond preparation at the beginning of the crop

Residual organic matter, bottom sludge, dead algae, biofilm, and pathogens from the previous crop remain in the pond.

• Inlet water containing toxic gases or contaminants

Groundwater or external water sources may contain high levels of NH₃ (ammonia) or NO₂⁻ (nitrite) and are often not tested before being pumped into the pond.

• Accumulation of uneaten feed and shrimp feces

Overfeeding or poor feed intake results in uneaten feed; shrimp feces accumulate and are not removed, causing waste buildup on the pond bottom.

• Anaerobic decomposition of organic matter

- Uneaten feed, feces, molted shells, dead shrimp, dead organisms, and decayed algae are not removed from the culture pond.

- They undergo anaerobic decomposition, generating toxic gases such as NH₃ (ammonia) and H₂S (hydrogen sulfide).

- High algal biomass or algal crashes also lead to environmental fluctuations and toxic gas formation.

• Unsuitable stocking density and farming practices

-Continuous culture without adequate time for pond renovation.

- High stocking density; insufficient clean water for exchange; minimal water exchange.

• Environmental parameters (pH, temperature, salinity, dissolved oxygen) directly influence the toxicity of harmful gases

Proper management of these parameters reduces the toxicity of ammonia and nitrite, even when their concentrations are elevated.

2. Clinical Signs and Impacts

- Soft-shell molting, incomplete molting, and slow growth.

- Shrimp gills show damage; shrimp swim weakly or lethargically; reddish appendages.

- Excessive dirty foam on the pond surface, algal die-off, and poor pond-bottom conditions.

- Rapid assessment can be conducted using a test kit to measure NH₃ and NO₂⁻ levels in the water.

3. Solutions for Toxic Gas Control

a) Preventive management from the beginning of the crop:

+ Remove sludge and thoroughly clean the pond bottom before stocking; create a siphoning pit to remove organic waste and feces during culture.

+ Monitor feeding trays carefully to avoid feed waste.

+ Check water quality 2–3 times per week to detect toxic gases early.

+ Increase aeration and maintain pH stability between 7.8 – 8.2.

b) Applying VIBO biological solutions for effective toxic gas control:

For Lined Ponds (HDPE ponds)

+ Daily: Continuously supplement organic-matter-degrading microorganisms to reduce toxic gases using EM-POWER at 20 L of biomass / 1,000 m³.

+ Every 2 days: Use SUPER BACILLUS BT, a specialized toxic-gas control product, at 500 g / 1,000 m³.

For Earthen Ponds

+ Every 2 days: Add organic-matter-degrading microorganisms using EM-POWER at 20 L of biomass / 1,000 m³.

+ Thorough toxic gas control with SUPER BACILLUS BT at 500 g / 1,000 m³.

4. Toxic Gas Treatment Solutions in Shrimp Ponds

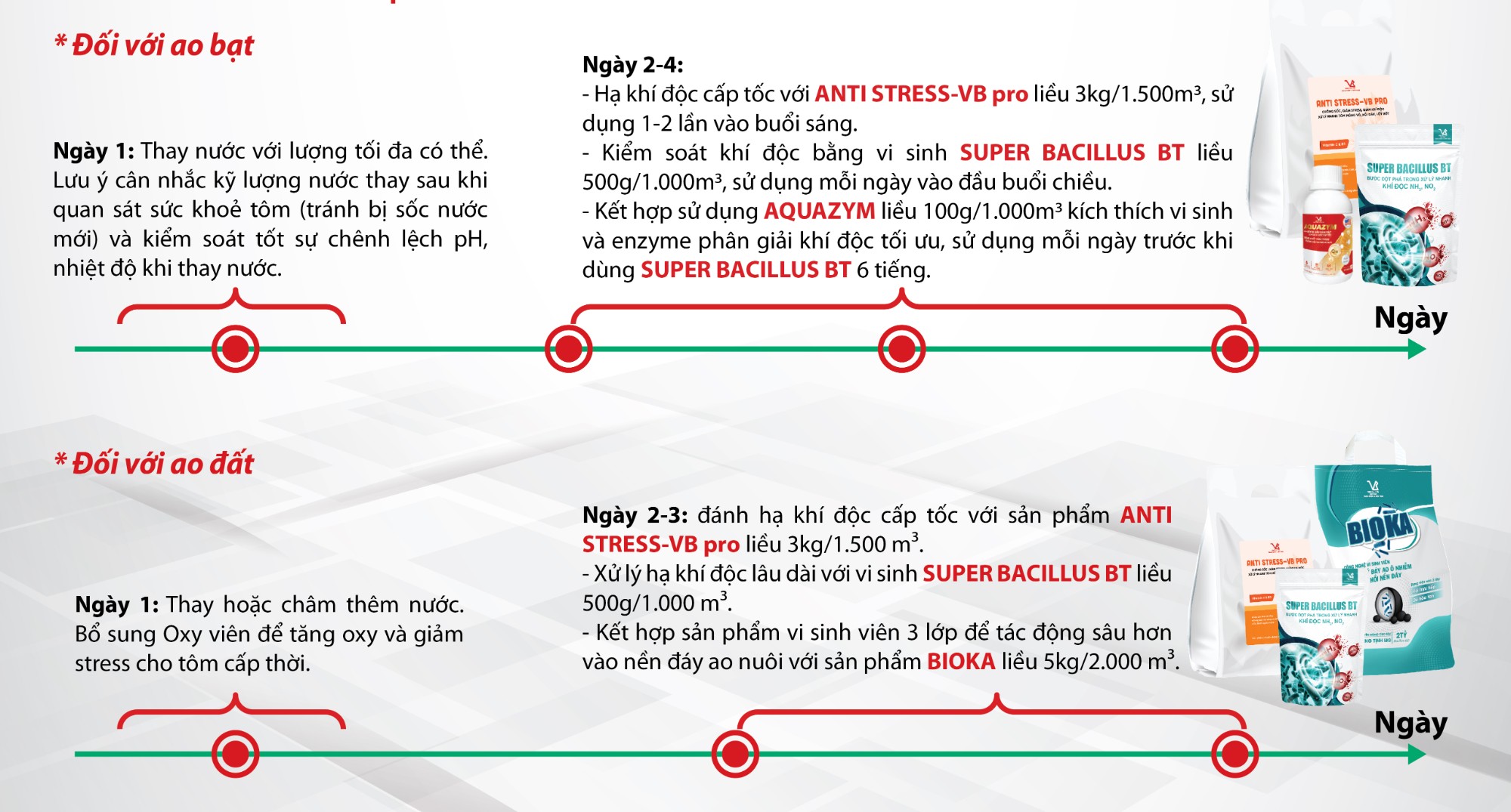

High-tech shrimp pond (bottom lining)

Day 1:

+ Replace water with the maximum amount possible.

+ Note: When exchanging water, observe shrimp health (to avoid stress shock) and check for fluctuations in pH and temperature when performing water exchange.

Days 2–4:

+ Rapidly reduce toxic gases using ANTI STRESS-VB pro at a dosage of 3 kg/1,500 m³, applied 1–2 times in the early morning.

+ Control toxic gases using the microbial product SUPER BACILLUS BT at 500 g/1,000 m³, applied daily in the afternoon.

+ Combine with AQUAZYME at 100 g/1,000 m³ to stimulate microbial activity and accelerate the breakdown of toxic gases; apply daily before using SUPER BACILLUS BT by 6 hours.

Traditional shrimp pond (earthen pond bottom)

Day 1:

+ Perform a water exchange or add new water.

+ Supplement with oxygen-enhancing products to increase dissolved oxygen and reduce stress for shrimp.

Days 2–3:

+ Apply rapid toxic-gas reduction treatment using ANTI STRESS-VB pro at 3 kg/1,500 m³.

+ Control long-term toxic gas using SUPER BACILLUS BT at 500 g/1,000 m³.

+ Combine with BIOKA at 5 kg/2,000 m³, a 3-layer microbial formulation that settles deeply into the pond bottom to improve bottom quality throughout the culture period.

Specialized shrimp article by the VIBO Technical Department